AQUAMATION ANALYSIS

IS A DISUSED FACTORY REALLY USED FOR AQUAMATION?

DO NOT PUBLISH

IMPORTANT SIDENOTE:

This analysis was undertaken in 2023 in a private disused factory and I should not have entered since it was private property

I entered via a hole in the fence and then through a small entry point in the warehouse area

I did feel this was allowed at the time since I did not have to break-in as such

I was apprehended by the Police on the two occasions I was there and should have taken heed not to enter any private property

THIS CONTENT IS HIGHLY DISTURBING AND DO NOT CONTINUE UNLESS EMOTIONALLY AND PSYCHOLOGICALLY STABLE

OUR CONTENT REPRESENTS A SMALL MINORITY

THERE IS SEEMINGLY A BATTLE BETWEEN GOOD AND EVIL AND NO BLAME IS APPLIED TO ANY COMPANY, ORGANISATION OR INDIVIDUAL

OVERVIEW

The Aquamation process and how humans can be liquified

The process is based on alkaline hydrolysis

The body is placed in a pressure vessel that is then filled with a mixture of water and potassium hydroxide and heated to a temperature around 160 °C (320 °F) at an elevated pressure which prevents boiling

The body is effectively broken down into its chemical components, which takes approximately four to six hours

Source: Wikipedia

AQUAMATION HIDDEN IN PLAIN SIGHT?

COULD THIS EMPTY FACTORY BE HIDING AN AQUAMATION FACILITY?

THE FACTORY IS A VERY POOR CONDITION

INDUSTRIAL, RUSTY, DIRTY AND CREEPY – IS IT THEIR INTENTION?

DO THEY WANT YOU TO EXIT?

EVEN THE LOGO HAS SEVERE SIGNS OF RUST AND CREATES A VERY NEGATIVE IMPRESSION

THEY WANT RUSTY AND OLD MACHINERY TO SEEM BROKEN - BUT THEY WORK AND ARE THEY BEING USED FOR NEFARIOUS REASONS?

STAGE 1

PREVIOUS OWNERS OF THE FACTORY

‘TRIUMPH FURNITURE LTD’

(CEASED TRADING OCTOBER 2019)

LAST ACCOUNTS SUBMITTED 3/6/2018. ‘APPOINTMENT OF ADMINISTRATOR’ ON 15/10/2019. FULL BREAKDOWN OF PROCESS MENTIONED - COMPANIES HOUSE RECORD

STAGE 2

PSYCHOLOGICAL TRICKS TO MAKE YOU WANT TO LEAVE THE FACTORY

AN OVERLOAD OF INDUSTRIAL MESSINESS, DANGERS AND CONFUSION OF OBJECTS ON THE FLOOR IS AIMED TO GET YOU TO LEAVE

THE GENERAL FEEL IS ONE OF A FACTORY FROM YESTERYEAR WHICH SEEMS VERY INDUSTRIAL, ABANDONED, SCRUFFY AND NOTHING WHATSOEVER HAPPENING HERE ANYMORE. WALK AWAY

THE GENERAL FEEL IS ONE OF A FACTORY FROM YESTERYEAR WHICH SEEMS VERY INDUSTRIAL, ABANDONED, SCRUFFY AND NOTHING WHATSOEVER HAPPENING HERE ANYMORE. WALK AWAY

STAGE 3

LIQUIFICATION TANKS

THE LIQUIFICATION TANKS AREA, SODIUM HYDROXIDE, PIPES UP TO THE CEILING AND CONTROL SYSTEMS

THERE ARE 6 TANKS IN TOTAL AND THIS IS ‘TANK 1’

THE TANK AREAS ARE ALL RUSTY, DIRTY, SEEMINGLY OLD AND OLD-TECH

AQUAMATION DOES NOT REQUIRE HIGH TECH EQUIPMENT - IT’S EFFECTIVELY A WASHING MACHINE PROCESS WITH 95% WATER AND 5% SODIUM HYDROXIDE

A MODERN LOOKING LAMINATED SIGN PORTRAYS THE NUMBER OF TANKS (TANK 1 IN THIS INSTANCE)

THERE ARE PIPES LEADING FROM MAIN UNITS (LARGE PIPE) AND ALSO THE SECONDARY UNITS (SMALLER PIPES) LEADING UPWARDS

THERE IS ALSO A WASTE PIPE WHICH FEED WASTE LIQUIDS INTO THE SEWERAGE AREA DOWNWARDS

THE LARGE PIPES GOING UPWARDS AND TERMINATING IN THE ROOF

LARGE PIPES TERMINATING AS CHIMNEYS IN THE ROOF

TANK 2

SAME CONFIGURATION WITH LARGE AND SMALL PIPES LEADING UPWARDS AND WASTE LIQUIDS INTO THE SEWERAGE SYSTEM DOWNWARDS

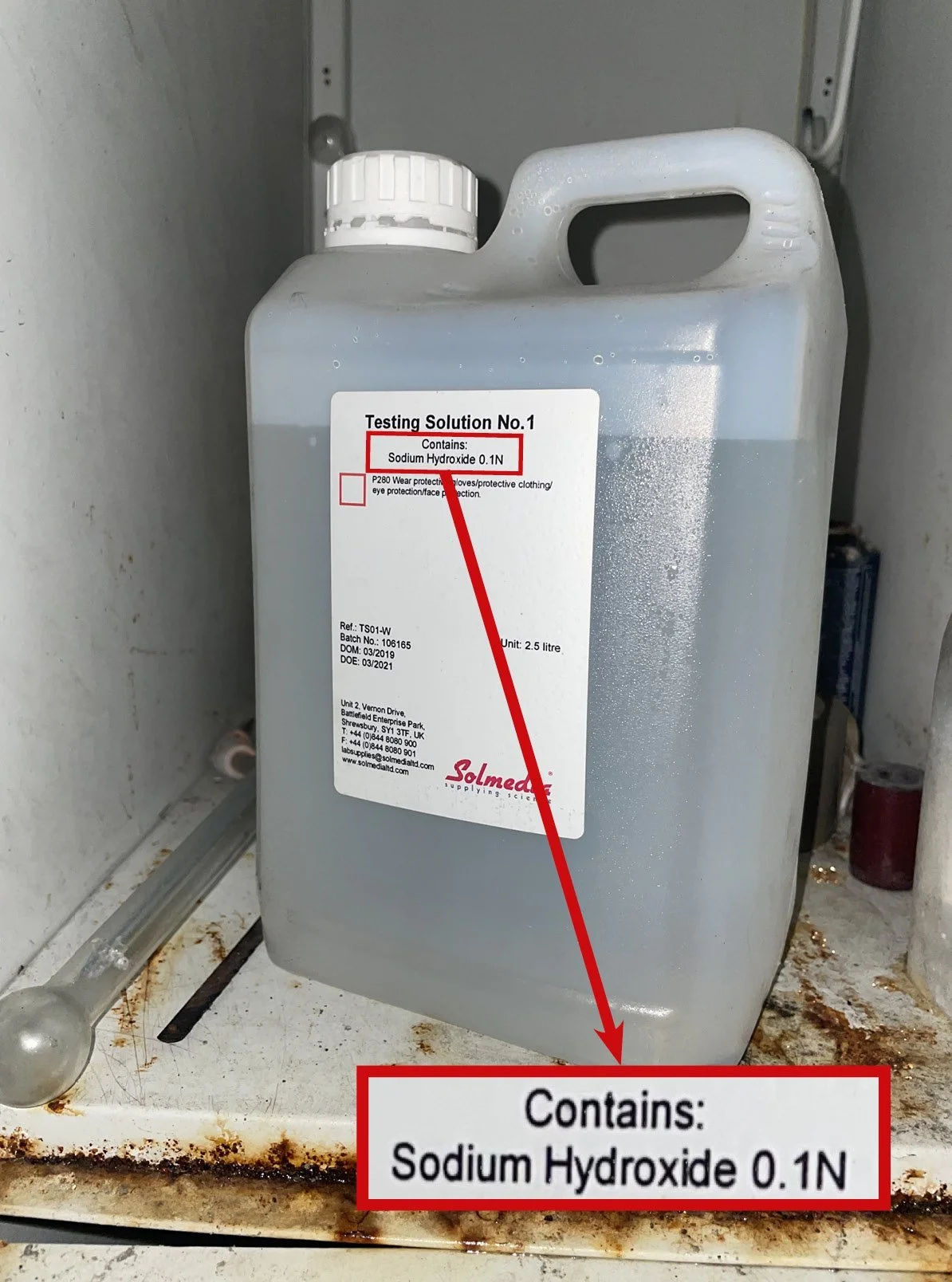

SODIUM HYDROXIDE IN AN OPEN CUPBOARD ADJACENT TO THE TANKS. THE DATE OF MANUFACTURE WAS 2019 AND THE EXPIRY 2021

THERE ARE ESTIMATED TO BE 160 MILLION CHEMICALS KNOWN TO HUMANS ACCORDING TO THE WORLD HEALTH ORGANISATION

THE ONLY CHEMICAL VISIBLE IN THE TANKS AREA IS THE PRECISE CHEMICAL REQUIRED IN THE AQUAMATION PROCESS - SODIUM HYDROXIDE

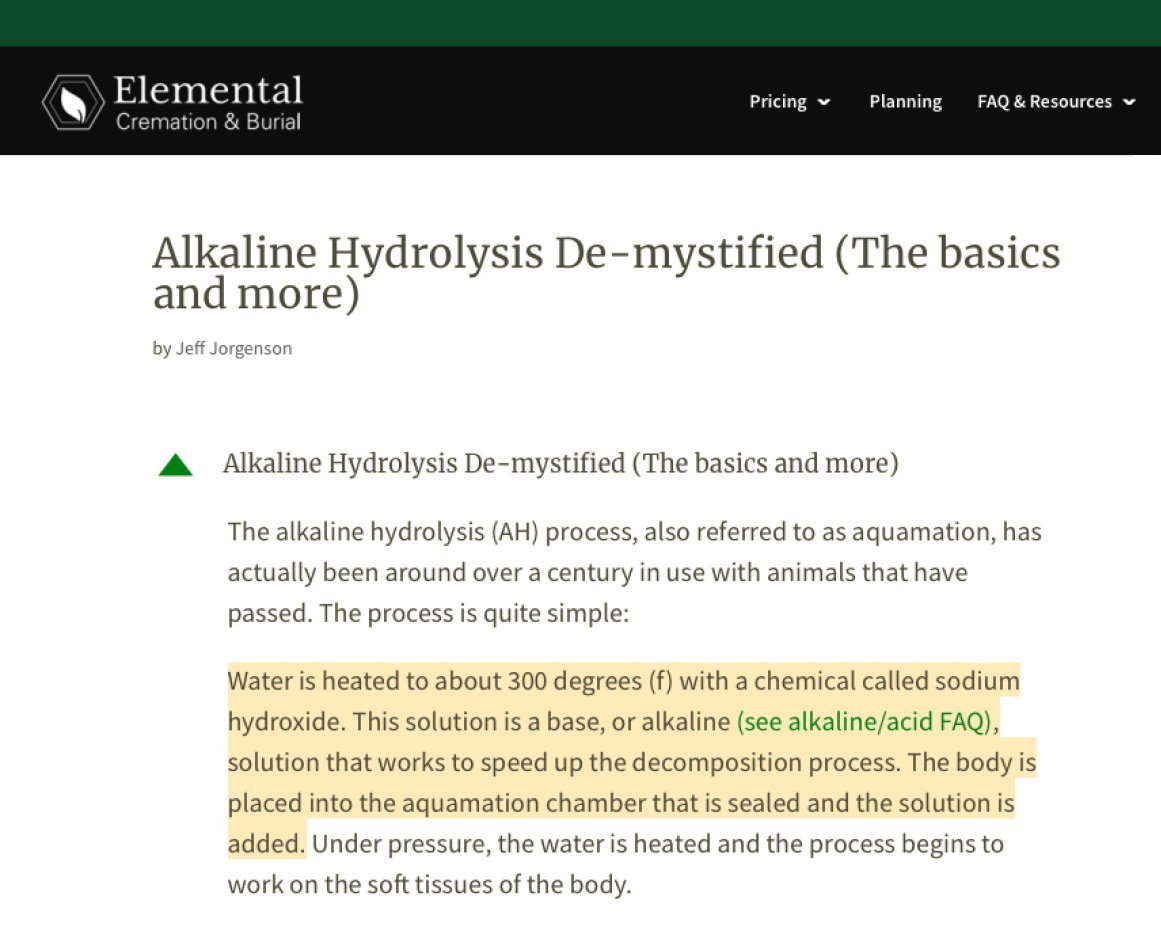

A GOOD TEXT BREAKDOWN ON THE AQUAMATION PROCESS BY ELEMENTAL CREMATION

TANK 4

A CLOSE-UP OF THE LARGE AND SMALL PIPES FROM EACH TANK

A CLOSE-UP OF THE WASTE PIPE WHICH FEEDS INTO THE SEWERAGE SYSTEM DOWNWARDS

THE TANKS LIQUID MANAGEMENT SYSTEM WHICH FEEDS TANKS 1-6

TANK 6 AND WASTE LIQUID PIPE GOING INTO THE SEWERAGE

STAGE 4

OVENS

THE OVENS AREA AND CONTROL SYSTEM

A RANDOM FURNITURE UNIT IS HANGING DOWN AND THIS MISDIRECTS YOUR THOUGHTS TO THE ORIGINAL FUNCTION OF THE FACTORY - BORING FURNITURE. … BUT WHY IS IT UPSIDEDOWN?

HOWEVER, IS THIS MISDIRECTION OF YOUR THOUGHTS DONE FOR A REASON OF TURNING BACK?

IF THE BRAIN PONDERS FOR MORE THAN 5 SECONDS THEN IT’S HIGHLY LIKELY MOST PEOPLE WILL NOT PROCEED ANY FURTHER SINCE THE BRAIN KILLS THE IDEA OF MOVING FORWARD

MOST PEOPLE WILL WALK AWAY AT THIS POINT

AFTER GOING DEEPER - YOU ENTER A DIFFERENT AND MORE BASIC, BARE CONCRETE AREA WHICH CONSISTS OF OVENS

THERE WERE TWO LARGE OVENS (ALTHOUGH THERE MIGHT BE MORE IN OTHER PARTS OF THE FACTORY) AND LARGE BAGS OF ASHES POSITIONED AROUND THE CORNER

IT’S NOT SURE AS TO THE SOURCE OF THE ASHES

AQUAMATION ITSELF DOES NOT LIQUIFY LARGE BONES, MAN-MADE OBJECTS LIKE TOOTH FILLINGS, PACEMAKERS ETC. THIS IS WHY CREMATION IN AN OVEN (DUE TO THE EXTREMELY HIGH TEMPERATURES) IS ALSO NEEDED SINCE IT MELTS THE REMAINING OBJECTS TO A SMALL AMOUNT ASHES PER BODY

AROUND THE CORNER IS THE OVEN CONTROLLER UNIT WHICH IS VERY OLD

THE OVEN CONTROLS ARE AS FOLLOWS:

(TOP BUTTONS CATEGORY) PRE-TREATMENT

(MIDDLE BUTTONS CATEGORY) PAINT CURING OVEN

(BOTTOM BUTTONS CATEGORY) DRY OFF OVEN

THIS UNIT WAS ALREADY OPEN UPON ARRIVING

NO MATTER WHAT THE BUTTON CATEGORIES STATE - THEY ARE ALL OVENS

STAGE 5

ELECTRICS

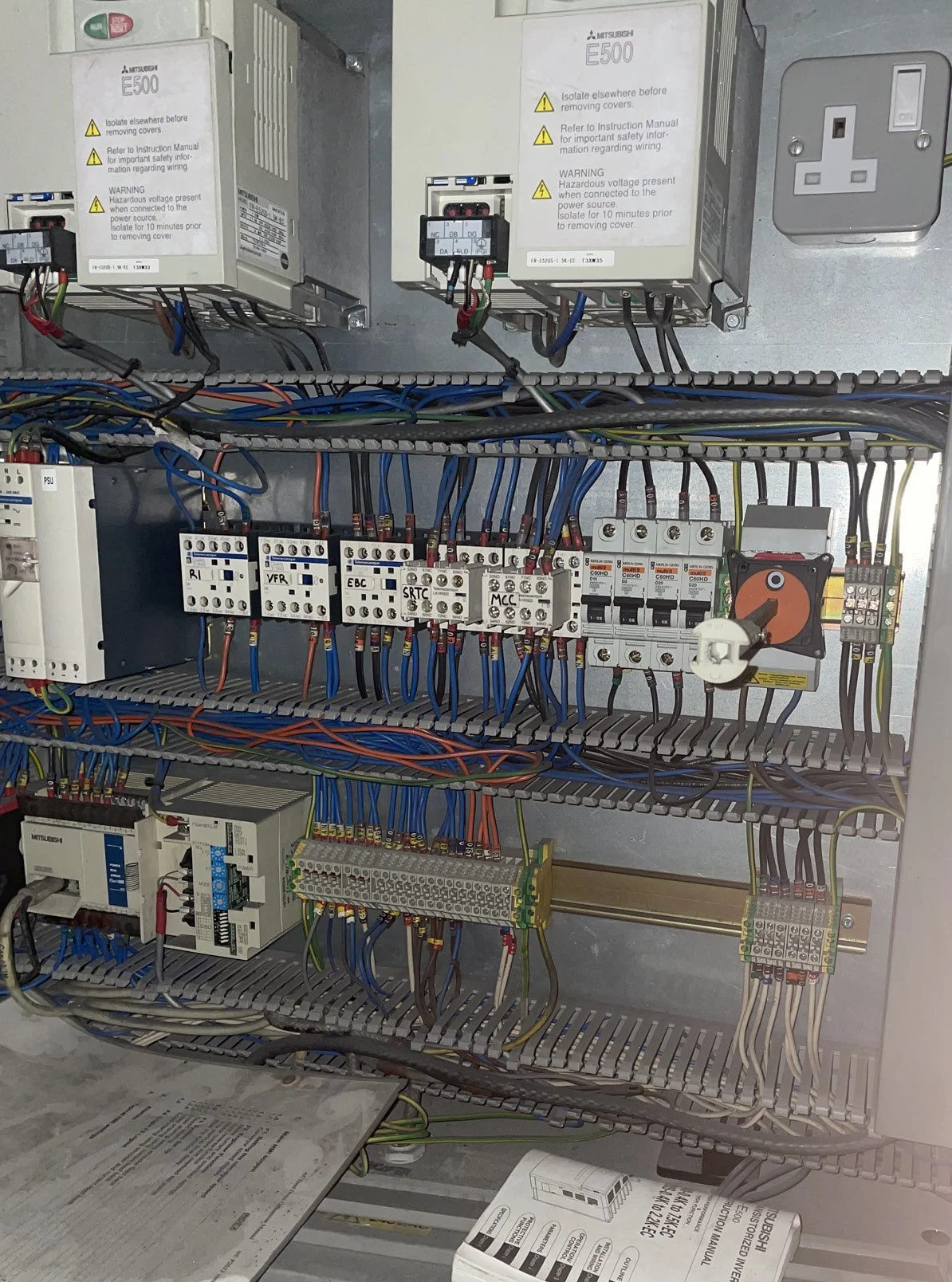

THE ELECTRICAL SYSTEM

A VERY MODERN, MANAGED, STRUCTURED AND ‘MISSION CRITICAL’ ELECTRICAL SYSTEM

YOU WOULD EXPECT A COMPARABLE ‘OLD’ ELECTRICAL SYSTEM (LIKE THE OVENS) - NOT THIS EXTREMELY PROFESSIONAL AND HIGH TECH CONFIGURATION

THE TANKS NEED A CLEAN AND CONSISTENT SUPPLY OF ELECTRIC TO FULFILL THE 95% WATER (HEATED TO 160 DEGREES CELSIUS) AND 5% SODIUM HYDROXIDE PROCESS TO PERFORM AQUAMATION

ADDITIONAL FUNCTIONS OF THE MODERN, MISSION CRITICAL ELECTRICAL SYSTEM

STAGE 6

REDUCING ROOF CORROSION DUE TO SODIUM HYDROXIDE

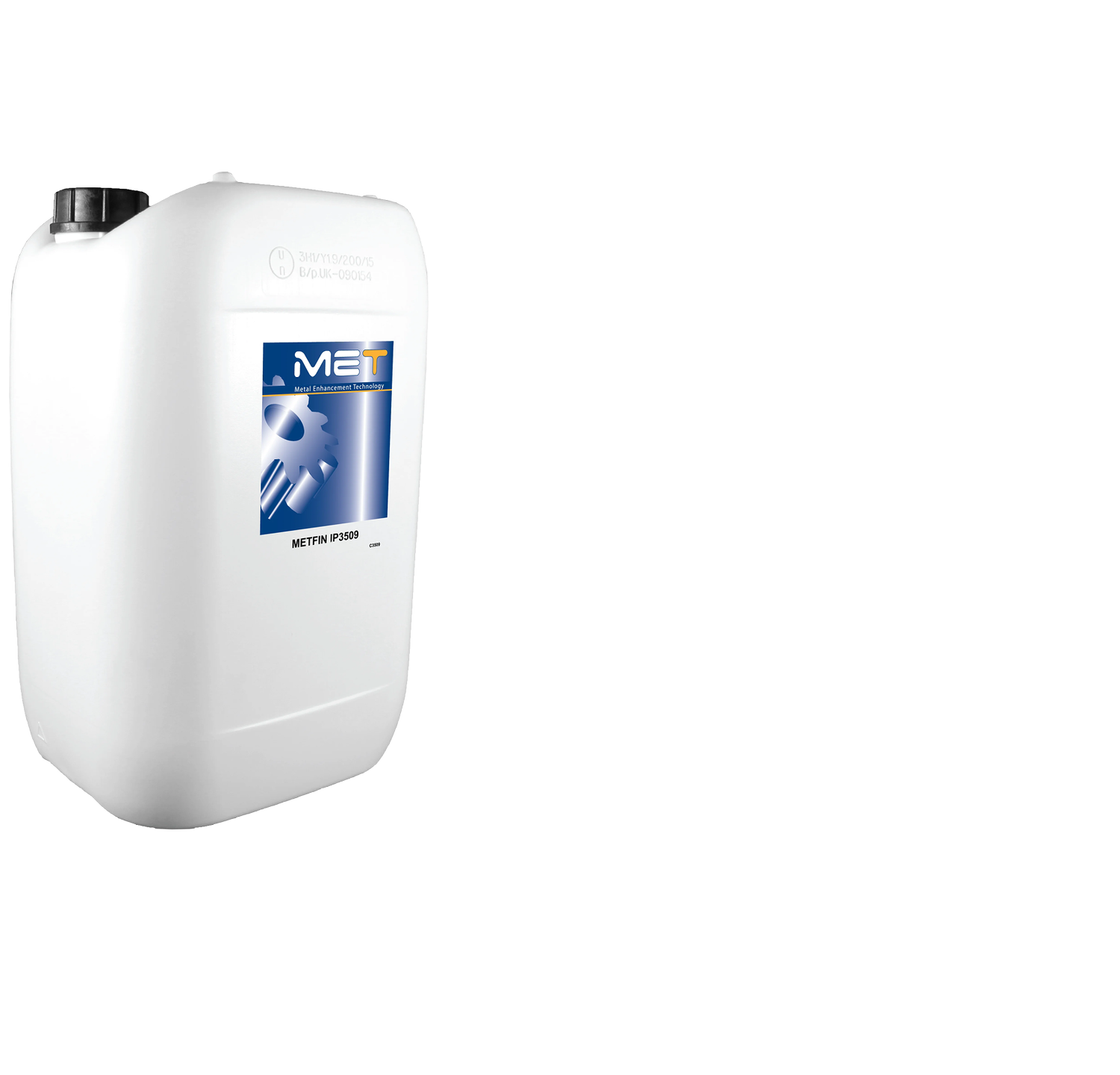

METFIN IP3509 IS BEING PUMPED INTO ROOF TO COMBAT CORROSION DUE TO SODIUM HYDROXIDE IN THE AQUAMATION PROCESS

THE AQUAMATION PROCESS WILL CREATE VAPOUR (FROM THE OUTLET PIPES) FROM THE TANKS WHICH CONTAINS SODIUM HYDROXIDE

IF METFIN IP3509 IS NOT USED - THE ROOF WILL CORRODE AND COLLAPSE

MORE DETAILS ON THIS PRODUCT CAN BE FOUND ON THE ORAPI WEBSITE AND ALSO SEE BELOW

METFIN IP3509 APPLIED TO THE ROOF TO AVOID CORROSION DUE TO SODIUM HYDROXIDE